Loading multiple orders

Overview

When scheduling orders in TilliT, it is possible to create a new order manually in the UI, however, it is more efficient to load the via the Excel Add-in. This allows you to collate all scheduled orders into a single document, then load all at once.

Template

If you need a template to get you started, you can download this Excel file: TilliT_Orders_Template.xlsx. It contains three (3) sheets; Schedule, OrderAttribute, OrderTolerance, each with the columns that TilliT requires. Each tab has an example entry. The columns in the template can also be generated when loading orders from TilliT to Excel.

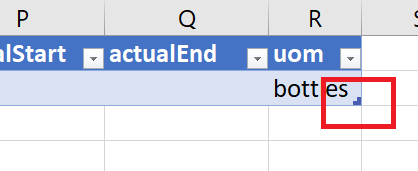

Be wary of where the last record is defined in the sheet:

Make sure it is on the last entry. If placed before the last entry, anything after it will not be saved. If placed after the last entry, blank entries will be created.

Loading Orders

Each order can contain order-level attributes and tolerances, which override any asset or material attributes and tolerances.

For this example, we will be referring to the sheets that can be found in the Excel template, but these same sheets are generated when loading TilliT to Excel, using the add-in.

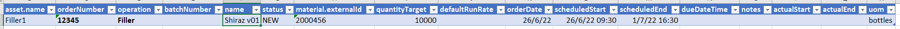

Schedule sheet

The main sheet is the Schedule sheet. This is where we input the main Order data. Below is a list of all the columns. Only some of the columns are mandatory. Any optional columns are marked.

id - leave blank to create new entries. If you supply a number, it will match this against an existing id in TilliT and update that entry.

asset.name - the name of the asset in TilliT you wish the order to run on, defined in Settings > Asset Hierarchy.

orderNumber - the order number (can be alphanumeric).

operation - as orders are sent per asset, you may have multiple orders with the same order number. The Operation defines which part of the job this is. This can be numbered (e.g., 100, 200, 300, etc) or named (e.g. Depal, Filler, Labeller, etc). Whichever makes sense to your business.

batchNumber (optional) - an optional field that allows to you add an extra level of defining your orders (e.g. you may use the same batch for a product sold under different brands).

name - this allows you to give the order a human-readable name. This allows you to describe what the order is, saving the need to look up order details elsewhere.

status - the default with new orders is to load them as NEW status, then progress the status within TilliT. However, you may wish to bring an order into TilliT ready or running. The three (3) statuses that can be used in this column are:

NEW - new order, simply loaded in TilliT

READY - defines the order as prepped and ready to start, when available.

RUNNING - define the order as running. Assets can only run one order at a time, by default, but this can be changed in the config.

material.externalId - the External ID of a material in TilliT that is preconfigured in Settings > Material Definition.

quantityTarget - the desired quantity of the product being produced.

defaultRunRate (optional) **** - the run rate of this specific order. If slower than the asset or material, then this will override that value.

orderDate - the date of the order.

scheduledStart - the date and time the order is scheduled to start.

scheduledEnd (optional) **** - the date and time the order is scheduled to complete.

dueDateTime - the date that the order is due to be delivered.

notes (optional) **** - any additional notes that other columns do not cover. This appears in the order details in TilliT.

actualStart - leave blank. This is filled in by TilliT as the order is started.

actualEnd - leave blank. This is filled in by TilliT as the order is completed.

uom (optional) - the Unit of Measure that the order uses (e.g. each, kg, boxes, etc).

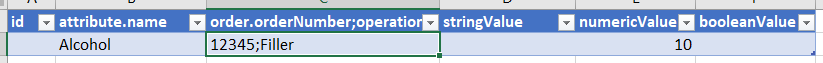

OrderAttribute sheet

Order Attributes are optional, but can open up a lot more functionality within TilliT. It can control which activities are available, can be used to in calculation item types as well as calculations on tolerances and active item & hidden expressions.

If you wish to add Order Attributes, use the OrderAttribute sheet and fill in the columns.

id - leave blank to create new entries. If you supply a number, it will match this against an existing id in TilliT and update that entry.

attribute.name - the name of the order attribute, as defined in Settings > Configuration > Attributes.

order.orderNumber;operation - the combined order number and attribute, separated by a semicolon. For example, if you have Order 12345 with Operation Filler, this value will be 12345;Filler.

[value option] - when entering a value, you will need to enter into the correct column, based on the type of attribute you are adding to:

stringValue - used for STRING or LINK type attributes. Allows you to input any alphanumeric value.

numericValue - used for NUMBER type attributes only.

booleanValue - used for BOOLEAN (true/false) type attributes only.

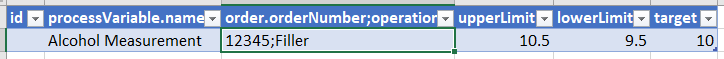

OrderTolerance sheet

Tolerances allow you to define what constitutes a pass or fail of an activity. These require pre-defined Process Variables to work.

If you wish to add Order Tolerance, use the OrderTolerance sheet and fill in the columns.

id - leave blank to create new entries. If you supply a number, it will match this against an existing id in TilliT and update that entry.

processVariable.name - the name of the Process Variable, as defined in Settings > Configuration > Process Variable.

order.orderNumber;operation - the combined order number and attribute, separated by a semicolon. For example, if you have Order 12345 with Operation Filler, this value will be 12345;Filler.

upperLimit (optional*) - value must be numeric. Sets the upper limit of the tolerance.

lowerLimit (optional*) - value must be numeric. Sets the lower limit of the tolerance.

target (optional*) - If either upperLimit and lowerLimit are given a value, target must be numeric. If both upperLimit and lowerLimit are left blank, the value can be alphanumeric and this value must be matched precisely.

* Note: while upperLimit, lowerLimit and target are all optional, you must set a value for at least one (1) of these columns.

Last updated

Was this helpful?