Changeovers

The idea of a changeover is to represent the time it takes to go from one production order to the next. Usually this time varies depending on the characteristics of the two orders (the from and to).

Configure Changovers

Create a Property

Your Property name must match a MaterialsProperty or Order Property Name

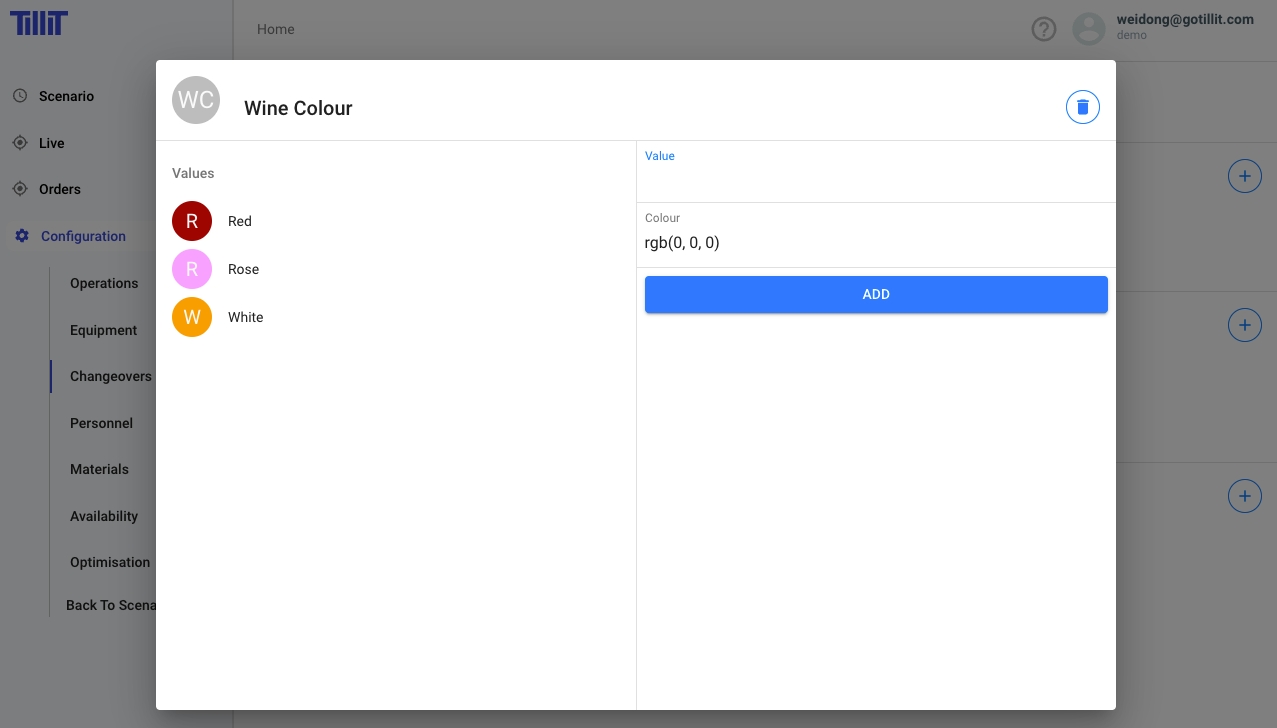

Enter a property name and click Add.

Double click on the Property then assign a Value and Colour.

The colour will be used when scheduling to display different material and optimisation property attributes. See example below.

Create a Changeover Set

A Changeover Set is used to define the From and To relationships for the changeover set based on the material attribute.

Below is a wine example where the matrix are a range of Changeovers between Wine Colour (e.g Red to White wine), Glass Bottle Size (750ml to 187ml) etc.

There will end up being a list of possible changeovers forming a matrix. The Optimiser will use this differential matrix to look for efficiency opportunities when optimising Orders.

Assign the Changeover Set on an Equipment

The last step is to assign a Changeover Set to an Equipment. You can apply different changeover sets to different equipment depending on the requirements for each situation.

In the example above, the Changeover Set for Glass is assigned to both Wine Bottle Packaging Lines as they use the same changeover times for both lines.

Last updated

Was this helpful?